S-Series Platform

Any Density. Any Scale.

Anywhere.

The Future of Data

Center Cooling is Here

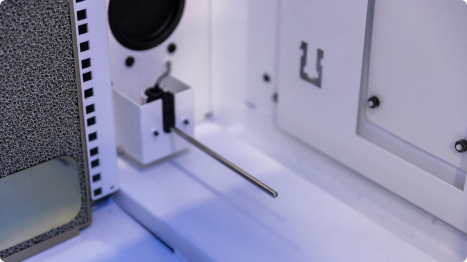

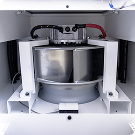

The DDC S-Series is a patented, high-performance data center cooling platform designed to meet the demands of AI and HPC workloads. Supporting up to 100kW air cooling and 600kW total with liquid-to-chip, each cabinet is modular, quiet, and ready to deploy—no special site prep required.

REQUEST A QUOTE3 models to support from low to highest density cooling

Base Model

Sample equipment supported includes H100, B100, B200, Storage Networking.

GPU Model

Supports 50-85kW air cooling and is field upgradeable to support higher densities as needed.

Max Model

Highest density model is field upgradeable and can support equipment such as GB200s.

Approved

NEMA 3R certified + fire suppression

Ultra-high density

Up to 600kW total density with liquid-to-chip

Easy to install

Roll in your racks or mount them in our integrated system

Low noise

Ultra-quiet operation for flexible site locations

Easy to combine

Modular scalability (1–1000+ cabinets)

No waste

Closed-loop system with zero water waste

The Challenge

AI and HPC are redefining the data center. Traditional cooling systems can’t keep up with the pace of next-gen infrastructure.

The Solution

DDC’s modular S-Series platform future-proofs your facility whether retrofitting, expanding, or building from scratch.

S-SERIES KEY FEATURES

Modular Design — Self-contained cabinets act as “data center in a data center” and deploy with ease

Flexible Cooling — Scale from 1kW to 600kW with air + liquid-to-the-chip integration

Smart Monitoring — Granular, real-time environmental control

Efficient & Quiet — Engineered to operate silently and sustainably

Built to Last — Walkable tops, sealed decks, and integrated protection

DDC allowed TierPoint to deliver the highest-density infrastructure with the lowest cost to build.